Foam Filled Fender Performance

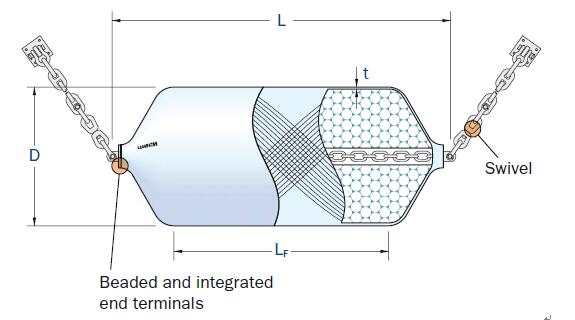

Foam filled fender is a high performance and heavy-duty floating fender system. Foam fender is made of polyurethane elastomer skin( or rubber skin), nylon reinforcement layer, and closed-cell resilient foam. It has high energy absorption and low reaction force and absorbs impacts even in an aggressive environment.

The closed-cell foam structure makes punctures a thing of the past. Every cell is separate and so water cannot migrate into the foam. Even after many years of active service, the foam core can be returned to the factory, re-skinned, and made ready for a new lease of life. No matter how badly abused, our foam fenders, will not burst or explode. Damage is rare, but if the worst should happen our foam fenders will still function until repairs are possible.

View videos about our Foam filled fender test Qc procedure

View videos about our Foam filled fender compression testing and measure :

Specification:

| Normal Size | Performance at 60%deflection | ||

| Diameter(mm) | Length(mm) | Reaction force(KN) | Energy absorption(KN.M) |

| 700 | 1500 | 13 | 3 |

| 1000 | 1500 | 17 | 5 |

| 1000 | 2000 | 26 | 7 |

| 1200 | 2000 | 28 | 10 |

| 1350 | 2500 | 42 | 16 |

| 1500 | 3000 | 59 | 24 |

| 1700 | 3000 | 63 | 29 |

| 2000 | 3500 | 86 | 47 |

| 2000 | 4000 | 102 | 56 |

| 2500 | 4000 | 118 | 64 |

| 2500 | 5500 | 122 | 82 |

| 3000 | 6000 | 182 | 123 |

| 3300 | 4500 | 234 | 189 |

| 3300 | 6500 | 172 | 153 |

| 3300 | 6500 | 279 | 248 |

View production videos about our marine fenders:

Product Testing

Before delivery, our Inspector from the Quality and Control Department checked the logo, appearance, and dimensions of the fender to ensure the product is satisfactory. We can also arrange third-party or classification society inspection at our site, such as BV, SGS, CCS, DNV-GL, LR, ABS, etc. Sometimes our customers would come to our site for inspection and every time the results are acceptable.

View testing videos about our rubber fenders:

Armored Floating Hose Pressure Testing

Product Packaging

After inspection, our products will be packaged in soon and deliver to customers.

Application

Foam filled fender is one of the floating rubber fender systems in the world now, they are widely used on ships, bridges, open ports, dolphin wharfs and etc. The buffer medium inside the fender is lightweight high-elastic closed-cell foam, which will make the fender afloat on the water, hence the operation location will not be influenced.