Pneumatic rubber fender (Yokohama Fender) is a prominent and high-pressure anti-collision system on marine application in the world now. It’s made of a strong rubber sheet with synthetic cords. The compressed air inside can keep the pneumatic fender floating on water. It’s also a shock absorber when ship to ship or ship to dock operations.

Product Features:

1. Easy to install and maintain

2. Reduce the shock/impact force

3. Large docks, bulk carries, large tankers, LPG vessels, ocean platforms, floating structures, harbor, wharf, and so on

4. Design and testing according to ISO17357:2002

Types of Pneumatic fender :

Type-I: Net type fenders

Pneumatic fender is covered and protected by wire, fiber, or steel chain with rubber sleeves or tires.

Type-II: Sling type fenders

Pneumatic fender is not protected by tires-net. It’s simple and lightweight.

View videos about our marine rubber fender production

| Normal Size | Performance(inner pressure:50Kpa,60%deflection) | Bodyweight (KG) |

Chain-net weight (KG) |

||

| Diameter (mm) |

Length (mm) |

Reaction force at GEA (KN) |

Guaranteed energy absorption (GEA)( KN.M) |

||

| 500 | 1000 | 64 | 6 | 23 | |

| 600 | 1000 | 74 | 8 | 28 | |

| 700 | 1500 | 137 | 17 | 58 | |

| 1000 | 1500 | 182 | 32 | 82 | 100 |

| 1000 | 2000 | 257 | 45 | 148 | 152 |

| 1200 | 2000 | 297 | 63 | 167 | 200 |

| 1350 | 2500 | 427 | 102 | 220 | 298 |

| 1500 | 3000 | 579 | 153 | 340 | 450 |

| 1700 | 3000 | 639 | 191 | 420 | 482 |

| 2000 | 3500 | 875 | 308 | 650 | 890 |

| 2000 | 4000 | 1008 | 368 | 740 | 1000 |

| 2500 | 4000 | 1381 | 663 | 1080 | 1180 |

| 2500 | 5500 | 2019 | 943 | 1180 | 1380 |

| 3000 | 5000 | 2422 | 1357 | 1980 | 2388 |

| 3000 | 6000 | 2906 | 1628 | 2400 | 2690 |

| 3300 | 4500 | 1884 | 1175 | 2380 | 2617 |

| 3300 | 6500 | 3015 | 1814 | 2980 | 3000 |

Performance of 50Kpa pneumatic fender :

| Normal Size | Performance(inner pressure:50Kpa,60%deflection) | Hull pressure(internal pressure) at GEA deflection (Kpa) |

||

| Diameter (mm) |

Length (mm) |

Reaction force at GEA(KN) | Guaranteed energy absorption (GEA)(KN.M) | |

| 500 | 1000 | 64 | 6 | 132 |

| 600 | 1000 | 74 | 8 | 126 |

| 700 | 1500 | 137 | 17 | 135 |

| 1000 | 1500 | 182 | 32 | 122 |

| 1000 | 2000 | 257 | 45 | 132 |

| 1200 | 2000 | 297 | 63 | 126 |

| 1350 | 2500 | 427 | 102 | 130 |

| 1500 | 3000 | 579 | 153 | 132 |

| 1700 | 3000 | 639 | 191 | 128 |

| 2000 | 3500 | 875 | 308 | 128 |

| 2500 | 4000 | 1381 | 663 | 137 |

| 2500 | 5500 | 2019 | 943 | 148 |

| 3300 | 4500 | 1884 | 1175 | 130 |

| 3300 | 6500 | 3015 | 1814 | 146 |

Performance of 80Kpa pneumatic fender :

| Normal Size | Performance(inner pressure:80Kpa,60%deflection) | Hull pressure(internal pressure) at GEA deflection (Kpa) |

||

| Diameter (mm) |

Length (mm) |

Reaction force at GEA(KN) | Guaranteed energy absorption (GEA)(KN.M) | |

| 500 | 1000 | 85 | 8 | 174 |

| 600 | 1000 | 98 | 11 | 166 |

| 700 | 1500 | 180 | 24 | 177 |

| 1000 | 1500 | 239 | 45 | 160 |

| 1000 | 2000 | 338 | 63 | 174 |

| 1200 | 2000 | 390 | 88 | 166 |

| 1350 | 2500 | 561 | 142 | 170 |

| 1500 | 3000 | 731 | 214 | 174 |

| 1700 | 3000 | 840 | 267 | 168 |

| 2000 | 3500 | 1150 | 430 | 168 |

| 2500 | 4000 | 1815 | 925 | 180 |

| 2500 | 5500 | 2653 | 1317 | 195 |

| 3300 | 4500 | 2476 | 1640 | 171 |

| 3300 | 6500 | 3961 | 2532 | 191 |

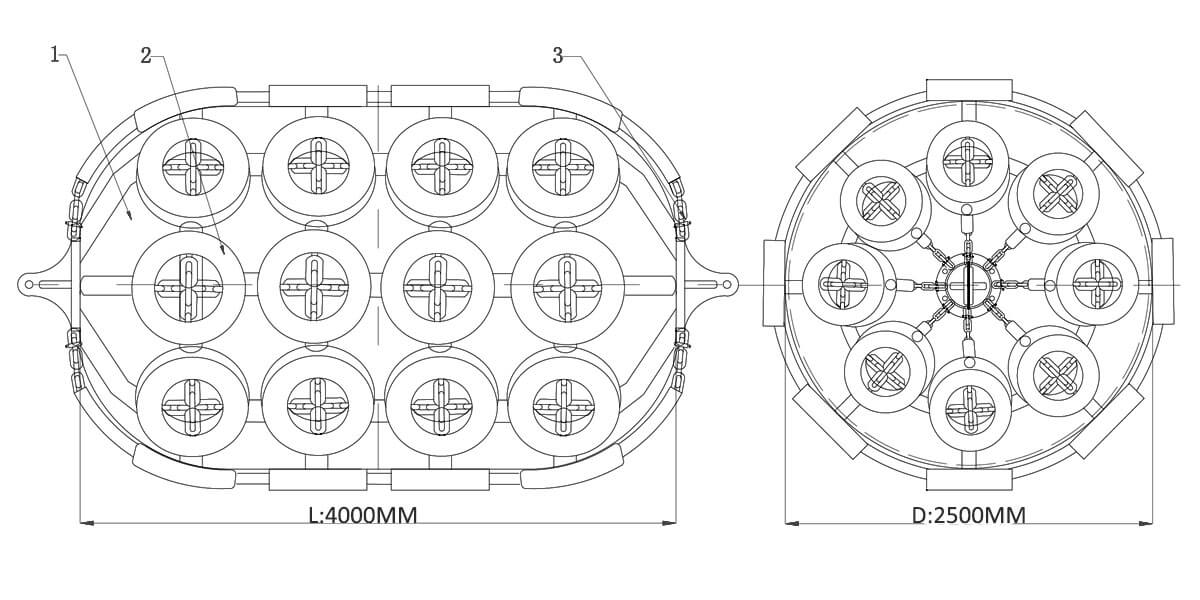

NOTE :

1ALL DIMENSIONS ARE IN MM UNLESS NOTED OTHERWISE.

2.REACTION FORCE:1381KN

3.ENERGY ABSORPTION:663KN-M

4.DEFLECTION:60%

5.PRODUCTION AND TEST COMPLY WITH 1S017357-1-2014.

6.MARKS:

D2500X4000MM

PRESSURE:—50KPA

NANJING DEERS

MADE IN CHINA

Production equipment

The size of the vulcanization tank determines the size of the pneumatic fender. The vulcanization tank in our factory allows us to meet the needs of most customers.

View testing videos about our rubber fenders:

Armored Floating Hose Pressure Testing

Product Testing

After the product is completed, in order to ensure the quality of the product, we will conduct self-test or third-party testing agency testing according to customer requirements, such as BV or SGS testing institutions, the testing content includes product size and weight and the most important compression testing. Our factory has its own large fender pressure testing machine, which performs the compression test of the product and generates a report. Before the test, the Pneumatic fender must remove the outer tire sheath or rope net and leave only the body.

- Body Test

- Fender Pressure Testing Machine

- Test Report

Packaging

The size and number of pneumatic fenders determine the way of packing. We have rich experience in packing. Normally larger fenders will use deflation to pack. We will give a set of inflatable fenders. Equipment, the customer can inflate and use the product normally after receiving the goods

View production videos about our marine fenders:

Application

Pneumatic rubber fender has been widely used in oil tankers, container ships, yachts, offshore platforms, large docks, military ports, large piers, etc.

The Pneumatic fender uses compressed air as the buffer medium to absorb the impact energy of the ship so that the ship can be more flexible and soft when docked, so as to achieve the effect of collision prevention, collision avoidance, and avoidance. Thus it is widely used in the transfer operation between ships and the berthing operation of ships.