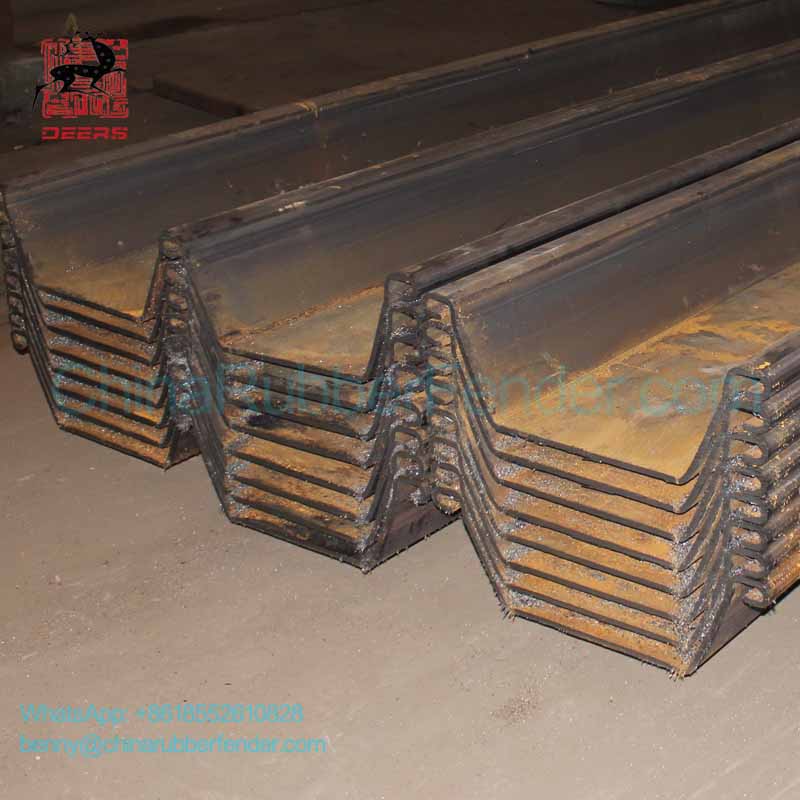

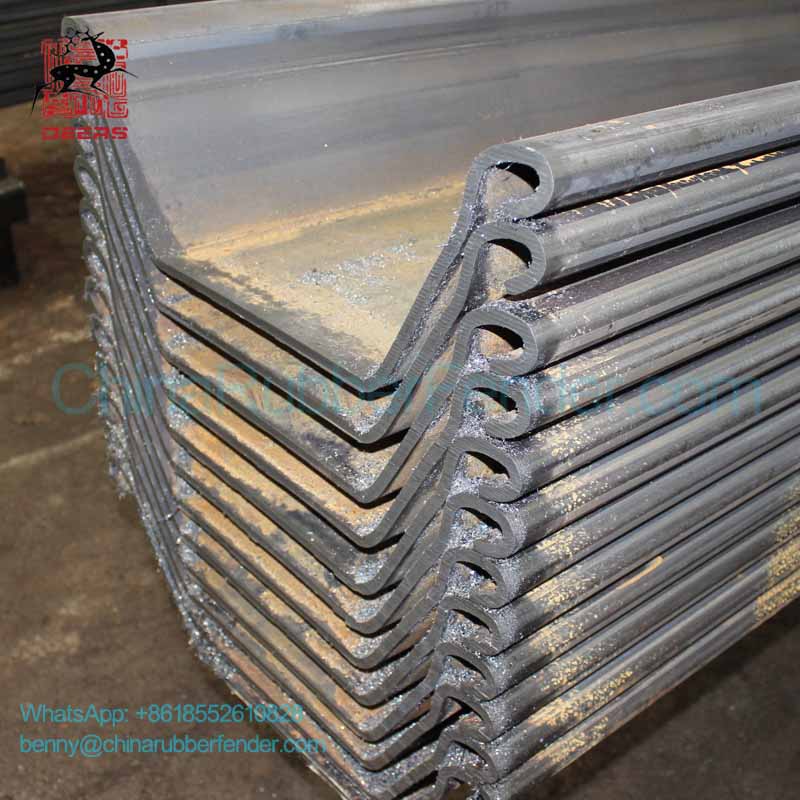

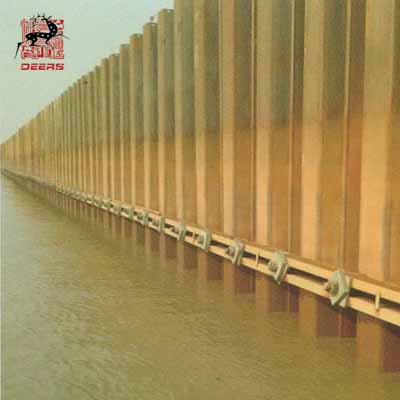

The U sheet pile series adopt advanced forming process. They are designed and produced for specific projects. Rapid production can meet immediate requirements, ensuring construction period. The flexibility of the interlock design allows the U steel sheet pile series to be applied in both temporary and permanent solutions.

The advantages of U sheet pile:

Symmetrical form has made it convenient for reuse. It also allows easy connections of various strutting system and tie rod connections, even under water.

Optimized section profile height and width, high steel grade and special design interlocking system to allow multiple reuses.

Combination of great wave depth and high steel grade give excellent statical properties with low weight.

Uniform section thickness for good driving stiffness.

Improve system width compared to standard sheet piling. Higher width reduces handling and installation time with usual driving equipment.

Higher width reduces the number of interlocks per meter run of wall and directly improves water tightness control of wall.

The video about steel sheet pipe production

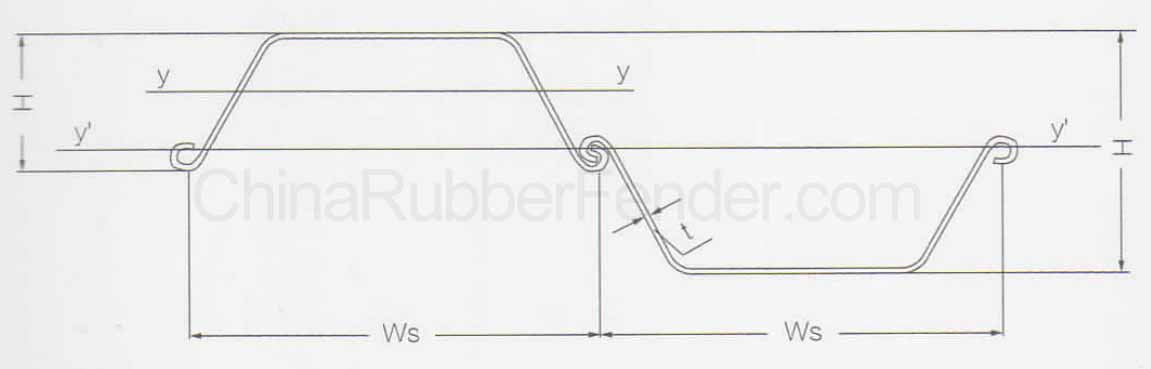

| Model | S (Single) | t | Ws | H | Ac | As | Wt | I | Z |

| D (Double) | mm | mm | mm | cm² | m²/m | kg/m | cm4 | cm3 | |

| 0T13-600 | S | 9 | 600 | 206 | 89 | 0.89 | 69.9 | 5330 | 430 |

| D | 1200 | 359 | 178 | 1.78 | 139.7 | 27820 | 1545 | ||

| 0T14-600 | S | 10 | 600 | 207 | 98.9 | 0.89 | 77.6 | 5930 | 480 |

| D | 1200 | 359 | 197.8 | 1.78 | 155.3 | 30670 | 1705 | ||

| 0T22-600 | S | 10 | 600 | 270 | 112.7 | 1.03 | 88.5 | 11620 | 720 |

| D | 1200 | 486 | 225.4 | 2.05 | 176.9 | 64300 | 2640 | ||

| 0T23-650 | S | 10.5 | 650 | 276 | 127.6 | 1.09 | 100.2 | 13850 | 1240 |

| D | 1300 | 488 | 255.2 | 2.17 | 200.3 | 72170 | 2960 | ||

| 0T24-650 | S | 11 | 650 | 276 | 133.6 | 1.09 | 104.9 | 14530 | 1300 |

| D | 1300 | 488 | 267.3 | 2.18 | 209.8 | 75370 | 3095 | ||

| 0T25-650 | S | 11.5 | 650 | 277 | 139.7 | 1.09 | 109.7 | 15230 | 1360 |

| D | 1300 | 488 | 279.5 | 2.18 | 219.4 | 78690 | 3230 | ||

| 0T26-650 | S | 12 | 650 | 277 | 145.9 | 1.09 | 114.5 | 15930 | 1410 |

| D | 1300 | 488 | 291.6 | 2.18 | 228.9 | 82000 | 3365 | ||

| 0T32-700 | S | 12 | 700 | 323 | 162 | 1.23 | 127.2 | 24050 | 1850 |

| D | 1400 | 580 | 324 | 2.45 | 254.3 | 131470 | 4535 | ||

| 0T33-700 | S | 12 | 700 | 335 | 168 | 1.26 | 131.9 | 26750 | 1940 |

| D | 1400 | 596 | 336.1 | 2.51 | 263.8 | 139020 | 4665 | ||

| 0T36-700 | S | 13 | 700 | 337 | 182 | 1.26 | 142.9 | 29390 | 2120 |

| D | 1400 | 598 | 363.9 | 2.52 | 285.7 | 152120 | 5090 | ||

| 0T39-700 | S | 14 | 700 | 339 | 196.1 | 1.26 | 153.9 | 31890 | 2270 |

| D | 1400 | 600 | 392 | 2.52 | 307.7 | 163660 | 5455 | ||

| 0T41A-700 | S | 15 | 700 | 400 | 210 | 1.26 | 164.9 | 34260 | 1730 |

| D | 1400 | 600 | 420 | 2.52 | 329.7 | 174120 | 5800 |