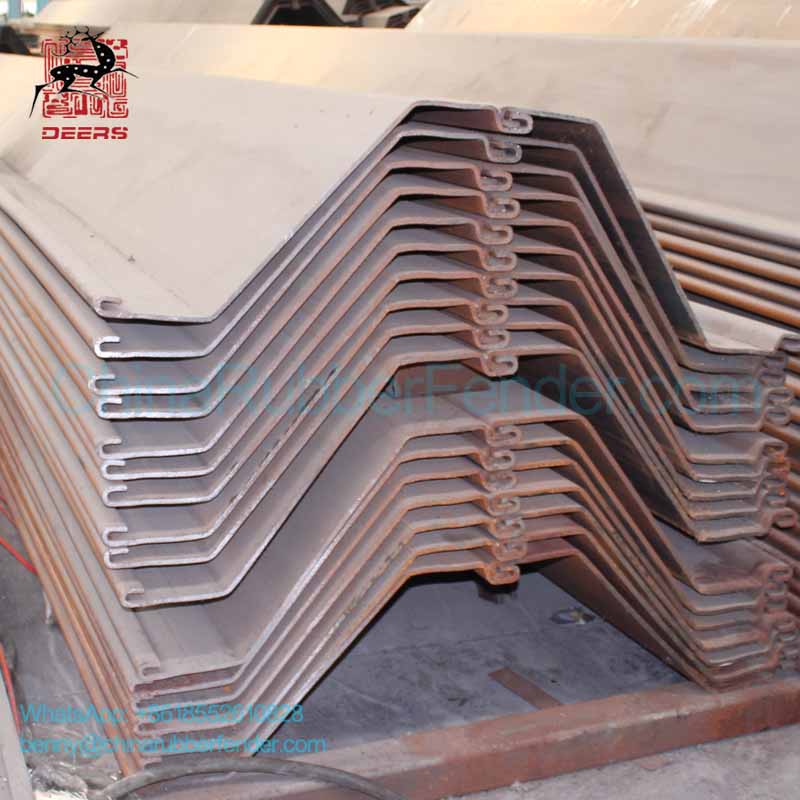

Advanced forming process allows persistent and precise Z section profile. The Z steel sheet pile is specially designed and produced locally with optimized section to facilitate immediate and fast delivery requirements. Finite element analysis was carried out to ensure product quality, consistency, as well as technical conformity.

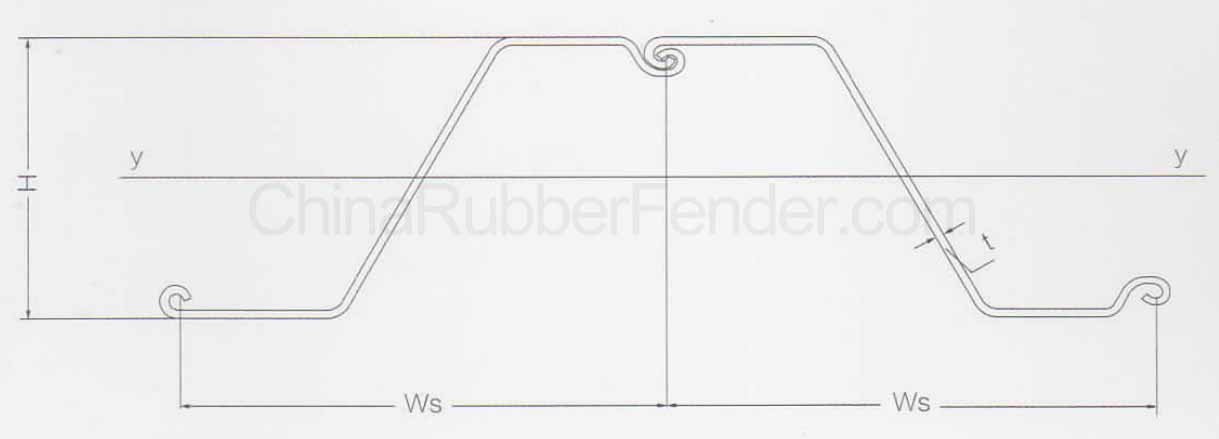

The essential characteristics of Z Sheet Pile are the continuous form of the web and the location of interlock symmetrically on each side of the neutral axis. Both aspects have a positive influence on the section modulus.

The advantages of Z sheet pile:

Interlocks located at the outer fibre thus give optimized section profile for high strength and low material weight.

High inertia enabling reduction of deflection for serviceability.

High steel grade provide efficient section with high bending moment resistant.

Uniform section thickness for good driving stiffness.

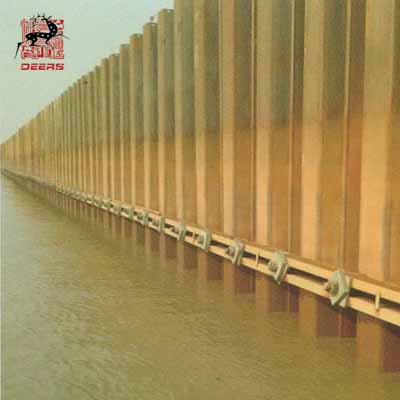

Improve system width compared to standard sheet piling. Higher width reduces handling and installation time with usual driving equipment.

Higher width will reduce the number of interlocks per meter run of the wall and directly improves water tightness control of wall.

The video about steel sheet pipe production

| Model | S (Single) | t | Ws | H | Ac | As | Wt | I | Z |

| D (Double) | mm | mm | mm | cm² | m²/m | kg/m | cm4 | cm3 | |

| OZ 14A | S | 7 | 675 | 399 | 76.1 | 0.98 | 59.7 | 19760 | 980 |

| D | 1350 | 152.2 | 1.97 | 119.5 | 39530 | 1980 | |||

| OZ 15A | S | 7.5 | 675 | 400 | 81.5 | 0.98 | 64 | 21140 | 1040 |

| D | 1350 | 163 | 1.97 | 128 | 42290 | 2120 | |||

| OZ 16A | S | 8 | 675 | 400 | 86.9 | 0.98 | 68.2 | 22500 | 1110 |

| D | 1350 | 173.8 | 1.97 | 136.5 | 45020 | 2250 | |||

| OZ 17A | S | 8.5 | 685 | 401 | 92.1 | 1 | 72.3 | 24350 | 1200 |

| D | 1370 | 184.2 | 2 | 144.7 | 48720 | 2435 | |||

| OZ 18A | S | 9 | 685 | 401 | 97.6 | 1 | 76.6 | 25740 | 1265 |

| D | 1370 | 195.2 | 2 | 153.2 | 51490 | 2570 | |||

| OZ 19A | S | 9.5 | 685 | 402 | 102.9 | 1 | 80.8 | 27120 | 1335 |

| D | 1370 | 205.8 | 2 | 161.7 | 54250 | 2700 | |||

| OZ 20A | S | 10 | 685 | 402 | 108.4 | 1 | 85.1 | 28490 | 1400 |

| D | 1370 | 216.8 | 2 | 170.2 | 56990 | 2840 | |||

| OZ 20 | S | 8 | 650 | 437 | 90.2 | 1.02 | 70.8 | 28150 | 1285 |

| D | 1300 | 180.4 | 2.04 | 141.6 | 56300 | 2575 | |||

| OZ 21 | S | 8.5 | 650 | 438 | 95.6 | 1.02 | 75.1 | 29850 | 1360 |

| D | 1300 | 191.2 | 2.04 | 150.2 | 59710 | 2730 | |||

| OZ 22 | S | 9 | 650 | 438 | 101.1 | 1.02 | 79.4 | 31550 | 1440 |

| D | 1300 | 202.2 | 2.04 | 158.7 | 63100 | 2880 | |||

| OZ 23A | S | 9.5 | 650 | 439 | 106.5 | 1.02 | 83.6 | 33240 | 1510 |

| D | 1300 | 213 | 2.04 | 167.3 | 66480 | 3030 | |||

| OZ 24A | S | 10 | 650 | 439 | 112 | 1.02 | 87.9 | 34920 | 1590 |

| D | 1300 | 224 | 2.04 | 175.8 | 69850 | 3180 | |||

| OZ 26 | S | 10.5 | 675 | 440 | 122.2 | 1.07 | 95.9 | 38730 | 1870 |

| D | 1350 | 244.4 | 2.13 | 191.8 | 77500 | 3530 | |||

| OZ 27 | S | 11 | 675 | 440 | 127.1 | 1.07 | 99.8 | 40510 | 1810 |

| D | 1350 | 254.2 | 2.13 | 199.7 | 81060 | 3685 | |||

| OZ 28A | S | 11.5 | 675 | 441 | 133 | 1.07 | 104.4 | 42280 | 1890 |

| D | 1350 | 266 | 2.13 | 208.7 | 84600 | 3840 | |||

| OZ 29A | S | 12 | 675 | 441 | 138.7 | 1.07 | 108.9 | 44040 | 1960 |

| D | 1350 | 277.4 | 2.13 | 217.8 | 88130 | 4000 | |||

| OZ 31A | S | 12.7 | 675 | 442 | 146.8 | 1.07 | 115.2 | 46500 | 2070 |

| D | 1350 | 293.6 | 2.13 | 230.4 | 93050 | 4215 | |||

| OZ 32 | S | 11 | 675 | 487 | 138 | 1.12 | 108.3 | 52030 | 2040 |

| D | 1350 | 276 | 2.24 | 216.7 | 104450 | 4290 | |||

| OZ 33 | S | 11.5 | 675 | 488 | 144 | 1.12 | 113.1 | 54300 | 2125 |

| D | 1350 | 288 | 2.24 | 226.1 | 109010 | 4475 | |||

| OZ 34A | S | 12 | 675 | 488 | 150.1 | 1.12 | 117.8 | 56740 | 2270 |

| D | 1350 | 300.2 | 2.24 | 235.7 | 113560 | 4655 | |||

| OZ 36 | S | 12.5 | 675 | 489 | 156.1 | 1.12 | 122.5 | 58950 | 2340 |

| D | 1350 | 312.2 | 2.24 | 245.1 | 118090 | 4835 | |||

| OZ 37 | S | 13 | 675 | 489 | 162.1 | 1.12 | 127.3 | 61210 | 2430 |

| D | 1350 | 324.2 | 2.24 | 254.5 | 122620 | 5015 | |||

| OZ 38A | S | 13.5 | 675 | 490 | 168.1 | 1.12 | 132 | 63460 | 2515 |

| D | 1350 | 336.2 | 2.24 | 263.9 | 127130 | 5200 | |||

| OZ 40 | S | 14 | 675 | 490 | 174.1 | 1.12 | 136.6 | 65700 | 2600 |

| D | 1350 | 348.2 | 2.24 | 273.3 | 131620 | 5370 | |||

| OZ 41A | S | 14.5 | 675 | 491 | 181.3 | 1.13 | 142.3 | 68650 | 2700 |

| D | 1350 | 362.5 | 2.26 | 284.6 | 137730 | 5610 | |||

| OZ 43 | S | 15 | 675 | 492 | 187.5 | 1.13 | 147.2 | 71230 | 2790 |

| D | 1350 | 375 | 2.26 | 294.4 | 142780 | 5805 |

Next: U Sheet Pile