Skype: evasky86

Whatsapp: +86 13376094258

E-mail: benny@chinarubberfender.com

Skype: evasky86

Whatsapp: +86 13376094258

E-mail: benny@chinarubberfender.com

Rubber Fenders supplied by Nanjing Deers Industrial Co., Ltd for marine or port applications. As specialized manufacturers of shipping fenders, we enhance collision avoidance capabilities through improved rubber fender performance and maximum strength offload platforms. Our marine rubber fenders provide effective ship berthing protection.

Heavy-duty fenders designed for port applications, providing superior protection for large vessels during berthing operations.

Marine fenders are the sort of fenders which are installed at harbor and provide protection to ship and dock at the time of docking.Thistype of fender includes cylindrical rubber fender, cell rubber fender, marine cone fende

Advanced design with excellent stability and shear resistance, ideal for modern port terminals and large vessels.

Features a hollow cylindrical body for high energy absorption and low reaction force, suitable for heavy-duty marine applications.

A simple and versatile fender type with good energy absorption, commonly used on quay walls and berthing structures.

Compact and durable, providing reliable protection for docks and shipyards under various berthing conditions.

Buoyant fender systems designed for ship-to-ship transfers and offshore applications where traditional fixed fenders aren’t suitable.

Air-filled floating fender used for ship-to-ship or ship-to-dock operations, offering high energy absorption and low hull pressure.

A floating fender with a closed-cell foam core and PU skin, designed for unsinkable performance and low maintenance.

Sleeves around a monopile and floats with water level, offering 360° protection and self-adjusting movement.

Designed for submarines and low-clearance vessels, combining water and air for vertical positioning and impact control.

Specialized fenders designed for various boat types and sizes, providing protection during docking and mooring in marinas and harbors.

Heavy-duty rubber fender mounted on tugboats, ideal for continuous pushing and rough docking operations.

A compact fender type with solid energy absorption, widely used on docks, tugboats, and workboats.

Similar to D fenders but with a keyhole-shaped profile for stronger mounting and improved stability.

Triple-leg design provides excellent grip and flexibility, mainly used on tugboats and service vessels.

Triple-leg profile ensures high stability and wear resistance, ideal for curved installations on harbor tugs.

Specialized fender solutions for unique applications and specific operational requirements in marine and industrial settings.

Combines features of D and rectangular fenders, offering higher strength and better friction grip

Straight-line profile with strong absorption capability, often used on narrow or limited-space installations.

Designed for dock corners to protect vessels and structures during angled berthing.

Box-shaped fender with robust construction, suitable for quay edges and heavy-duty berths.

A rotating cylindrical fender mounted on a pivot, suitable for dynamic berthing angles.

Comprehensive range of high-quality accessories for marine fender systems

Marine-grade U-rings designed for stable and corrosion-resistant anchoring of fender components. Suitable for long-term use in marine environments.

High-strength welded link chains, galvanized for durability and corrosion resistance. used in tension and support systems for marine fenders.

Heavy-duty shackles made from drop-forged steel with hot-dip galvanized coating. Used for securely connecting chains and fittings in fender systems.

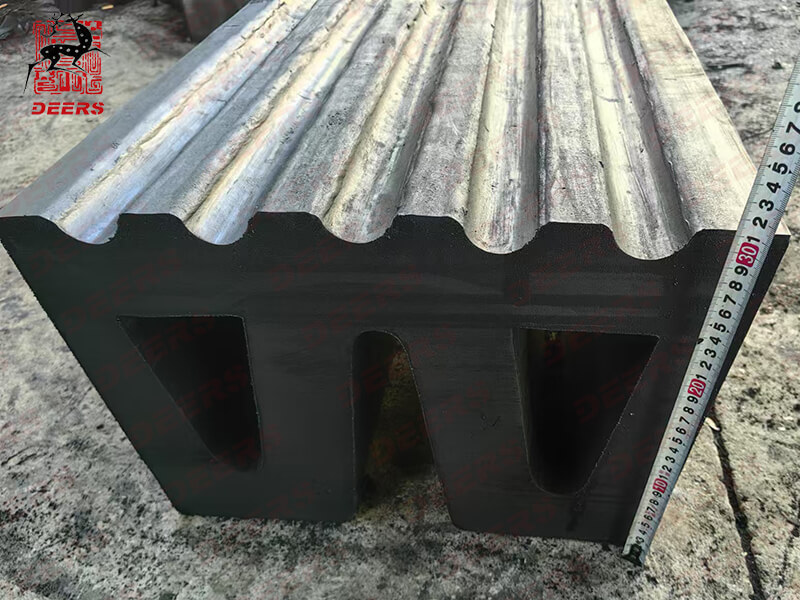

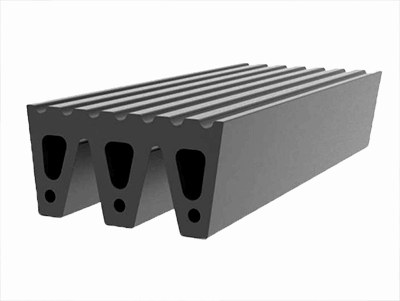

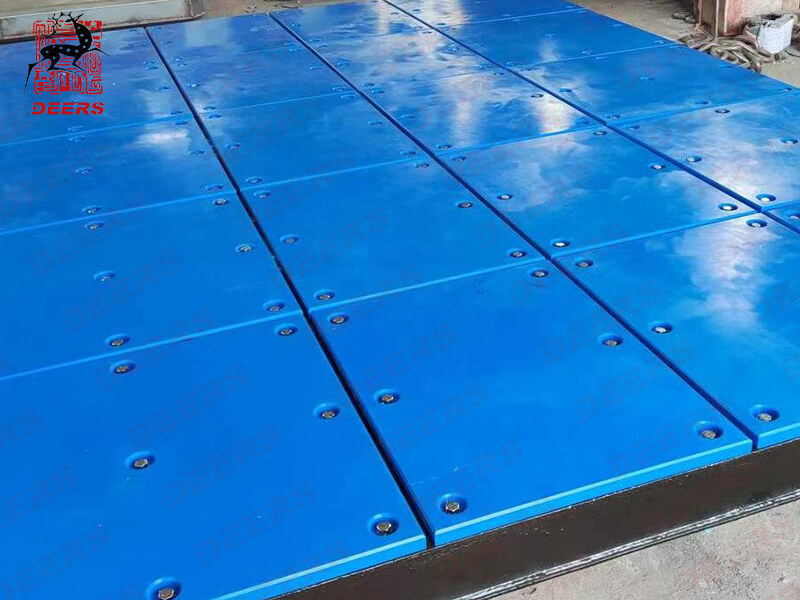

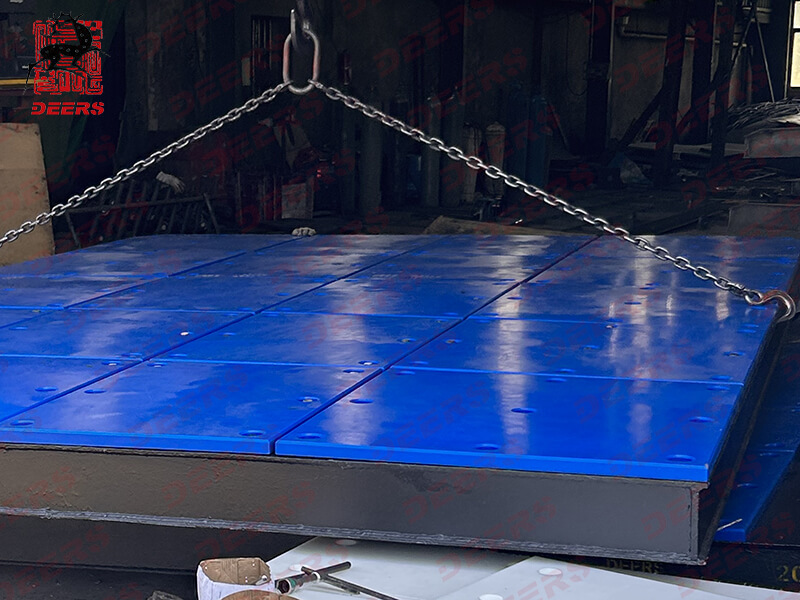

Steel-reinforced panels with custom design to distribute impact load. Typically fitted with UHMW-PE facing pads for reduced vessel friction and wear.

Ultra-high molecular weight polyethylene pads mounted on fender panels. Provide low-friction contact with vessels and excellent resistance to abrasion and UV.

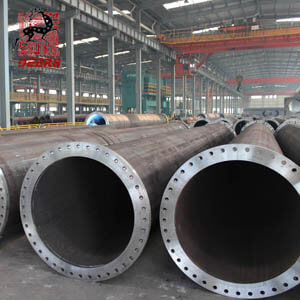

Dredging Hoses supplied by Nanjing Deers Industrial Co., Ltd are engineered for reliable performance in harsh marine and dredging environments.As trusted suppliers in the dredging industry, we deliver flexible, abrasion-resistant hose solutions for transporting slurry, sand, or gravel between dredgers and discharge areas. Our hoses ensure smooth material flow and durability in offshore and port operations.

A self-floating hose is a type of dredging pipeline with built-in buoyancy layers that enables it to float on the water surface without the need for additional pontoons.It is widely used in marine and offshore dredging operations for transporting slurry, sand, gravel, or tailings. Compared to traditional steel or rubber pipes, self-floating hoses offer easier deployment, flexible layout, and improved operational efficiency.

Constructed with a wear-resistant rubber inner layer and closed-cell foam flotation layer, this hose is suitable for general-purpose dredging applications.

Reinforced with hard steel rings in the inner layer to enhance wear resistance, ideal for transporting highly abrasive materials like gravel and crushed rock.

Lined with embedded ceramic rings or plates on the inner wall, offering superior wear and erosion resistance for highly abrasive media.

Specially designed for bow discharge operations on dredgers, this hose connects to the vessel’s bow and works with a swivel tower or rotary joint.

Suction and discharge hoses are flexible rubber pipelines used in dredging operations to transport slurry, sand, silt, or gravel between dredgers and onshore/offshore locations. These hoses are designed for negative pressure suction or positive pressure discharge applications. With excellent abrasion resistance and structural strength, they are essential components in both floating and submerged dredging systems.

Designed to withstand negative pressure, the suction hose is typically connected to the dredger’s inlet for drawing in dredged materials.

Used on the outlet side of dredging systems to transport slurry under positive pressure, commonly installed on decks or floating pipelines.

Fitted with embedded hard steel rings inside the rubber layer to resist severe abrasion, transporting sharp or heavy materials such as stones and gravel.

Equipped with internal ceramic liners (rings or tiles) for outstanding protection against erosion, particularly in high-abrasion dredging operations.

A combined pipeline system refers to the integrated use of various types of pipes and flotation units to create a customized dredging or slurry transport solution. These systems typically consist of steel pipes, HDPE pipes, pipe floats, and rubber floaters. Designed for both floating and submerged applications, the combined pipeline ensures efficient material flow, stable buoyancy, and adaptability to complex dredging environments.

Pipe floats are HDPE or PE shells filled with PU foam or air, clamped around steel or HDPE pipes to provide buoyancy in floating dredging pipelines.

High-density polyethylene (HDPE) pipes are lightweight, corrosion-resistant, and flexible, commonly used in long-distance or floating dredging pipelines.

Steel pipes offer rigid structure and high-pressure resistance, often used as the mainline in dredging discharge systems, either floating with floats or laid on the seabed.

Rubber floaters are a hybrid of rubber hoses and built-in buoyancy, used to provide floating support and impact resistance for pipeline systems.

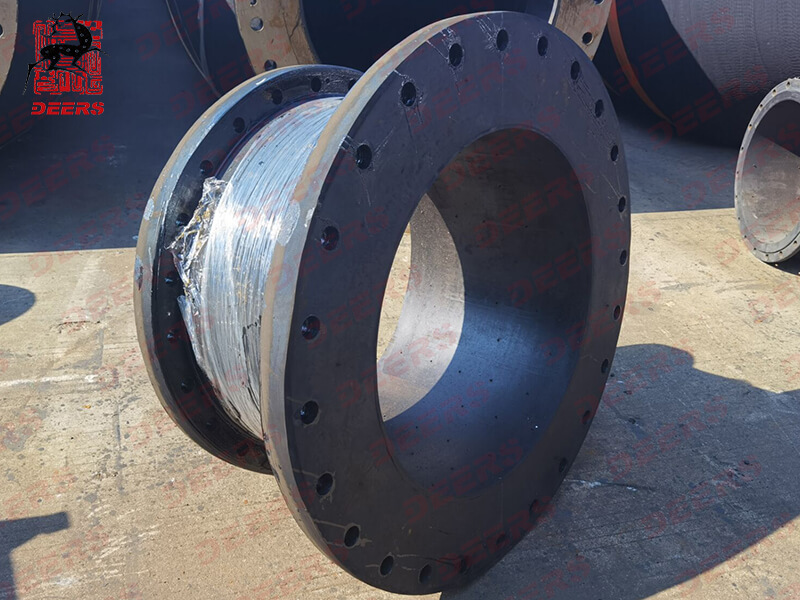

Ball Joints provide flexible angular movement in dredging pipelines, while Expansion Joints absorb axial, lateral, and angular movements. Together, they ensure smooth slurry flow, reduce structural stress, and compensate for thermal expansion and vibration in marine operations.

Ball joints are mechanical swivel connectors that allow rotational and angular movement in all directions, commonly used in floating pipeline systems and dredger bow discharge units. They ensure flexibility and secure operation in dynamic marine conditions.

Expansion joints are flexible connectors installed between pipe sections to absorb thermal expansion, contraction, and vibration in dredging and slurry pipelines. They help prevent structural stress, misalignment, and leakage, especially in long or dynamic piping systems.

Ceramic expansion joints are specially designed to absorb thermal movement and vibration while providing exceptional wear resistance in high-abrasion slurry transport systems. The inner lining is made of ceramic rings or tiles, making them ideal for severe dredging or mining applications where conventional rubber joints may fail.

Mooring Equipment supplied by Nanjing Deers Industrial Co., Ltd is designed to provide secure and efficient vessel mooring in various marine and port environments. We offer a complete range of mooring solutions, including bollards, anchors and ropes, to ensure safe berthing and station-keeping under demanding conditions.

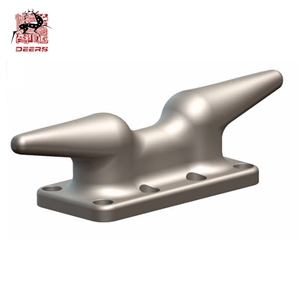

A bollard is a strong, fixed post installed on docks, wharves, or quays, used to secure mooring lines and keep vessels safely in place. Bollards are available in various designs and load capacities to meet the needs of different port operations.

T-Head Bollard features a T-shaped top that allows secure mooring from both sides. Widely used in ports for handling high loads.

Kidney Bollard has a curved, compact shape that guides mooring lines smoothly. Ideal for general-purpose mooring in limited spaces.

Staghorn Bollard is named for its branching horn-like arms, providing multiple line attachment points.

Cleats Bollard is a small-sized mooring fixture with two arms, commonly used for small boats and light-duty mooring on piers and pontoons.

Bitt Bollards, including single and double types, are vertical post-style mooring fixtures designed to handle high loads in commercial docks and terminals.

An anchor is a heavy device used to secure a vessel to the seabed, preventing drifting due to wind or currents. Designed for stability and holding power, anchors are essential for offshore mooring and emergency positioning.

Offshore Anchors are heavy-duty devices used to secure floating structures or vessels in open sea by embedding into the seabed. They ensure stable positioning under harsh marine conditions.

Delta Anchor is a high-holding-power anchor with a plow-shaped design, widely used for offshore and marine mooring due to its excellent penetration and stability.

Danforth Anchor features a lightweight, flat-fluke design that offers strong holding power in soft seabeds like sand and mud. It is commonly used for temporary mooring in offshore and coastal applications.

Hall Anchor is a stockless anchor with a heavy, pivoting fluke design, widely used on large commercial vessels for reliable holding in various seabed conditions.

Stockless Anchor is a commonly used ship anchor with a simple, pivoting shank and fluke design, ideal for large vessels due to its easy handling and compact storage.

Workboat Anchor is a compact and practical anchoring solution designed for tugs, barges, and service vessels operating in coastal and inland waters.

Pool Anchor is a type of stockless anchor with a compact, balanced design, offering reliable holding performance for large vessels across various seabed conditions.

Kedge Anchor is a lightweight, portable anchor used for small vessels or as a secondary anchor to assist in maneuvering and positioning.

AC-14 Anchor is a high-performance plow-type anchor designed for strong holding power in a variety of seabed conditions, widely used in offshore mooring and marine applications.

Mooring rope is a high-strength line used to tie ships to docks or other mooring structures. Made from synthetic fibers or steel wire, these ropes offer excellent tensile strength, durability, and resistance to abrasion and marine conditions.

Nylon Rope is a versatile synthetic rope known for its high strength, elasticity, and resistance to chemicals, commonly used in mooring and towing.

Polyamide Rope, typically nylon, offers strong and elastic properties suitable for demanding mooring and marine operations.

This rope is made of high-quality nylon synthetic fibers, designed for secure mooring with enhanced durability and elasticity.

3-Strand, 4-Strand, and 6-Strand ropes are classic twisted ropes offering reliable performance and easy handling for general maritime use.

6-Strand Nylon Composite Rope is made of six intertwined nylon strands, providing excellent strength and flexibility for marine mooring applications.

Made with a braided polyester core and cover, this rope offers low stretch, high strength, and long service life in marine conditions.

This rope combines a braided nylon core and cover, delivering elasticity and strength ideal for absorbing shock loads during mooring.

This rope blends nylon and polyester fibers in a double braid construction, combining stretch and low creep for balanced mooring performance.

Built with ultra-high molecular weight polyethylene fibers , this rope offers exceptional strength with minimal stretch.

This rope features an inner and outer braided structure, offering enhanced strength, wear resistance, and load-bearing capacity for demanding mooring applications.

This hybrid rope integrates steel wire cores with synthetic fiber covers, combining tensile strength with flexibility for heavy-duty mooring.

This rope combines the strength and low stretch of polyester with the elasticity of nylon, offering balanced performance for various mooring needs.

Made by blending polypropylene and polyester fibers, this rope offers buoyancy from polypropylene and strength from polyester, ideal for floating mooring applications.

Constructed from aramid fibers , this rope delivers high heat resistance and superior strength, suitable for extreme marine and industrial environments.

A durable and low-stretch rope widely used in marine mooring due to its excellent strength retention in wet conditions.

A lightweight rope that floats on water, making it ideal for surface mooring and general marine use where buoyancy is needed.

Made from ultra-high molecular weight polyethylene , this rope offers exceptional strength with ultra-low stretch, ideal for demanding mooring tasks.

Copyright © 2024 Nanjing Deers Industrial Co.,Ltd All Rights Reserved.