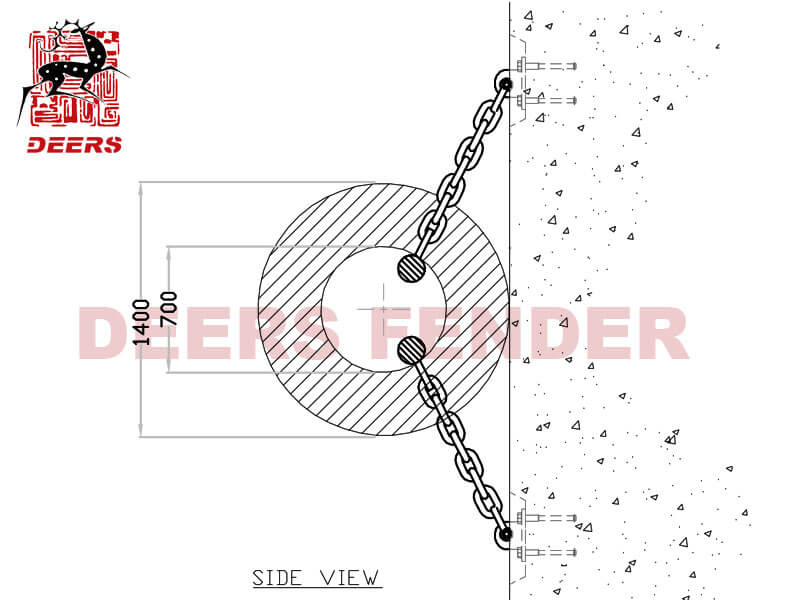

BASIC INFO

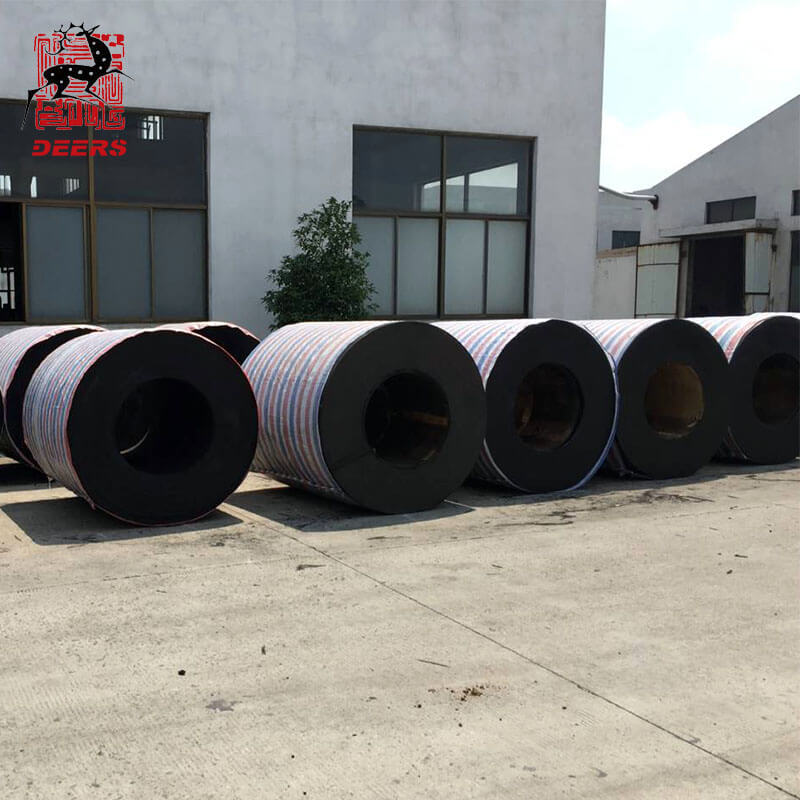

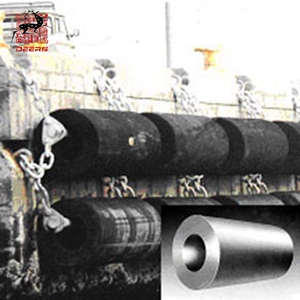

Production

Testing Packaging Cases

View testing videos about our rubber fenders:

Armored Floating Hose Pressure Testing