Skype: evasky86

Whatsapp: +86 13376094258

E-mail: benny@chinarubberfender.com

Skype: evasky86

Whatsapp: +86 13376094258

E-mail: benny@chinarubberfender.com

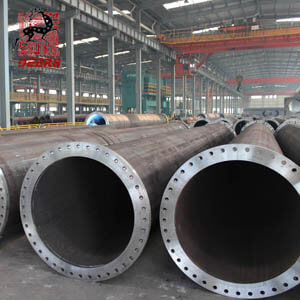

Dredging Hoses supplied by Nanjing Deers Industrial Co., Ltd are engineered for reliable performance in harsh marine and dredging environments.As trusted suppliers in the dredging industry, we deliver flexible, abrasion-resistant hose solutions for transporting slurry, sand, or gravel between dredgers and discharge areas. Our hoses ensure smooth material flow and durability in offshore and port operations.

A self-floating hose is a type of dredging pipeline with built-in buoyancy layers that enables it to float on the water surface without the need for additional pontoons.It is widely used in marine and offshore dredging operations for transporting slurry, sand, gravel, or tailings. Compared to traditional steel or rubber pipes, self-floating hoses offer easier deployment, flexible layout, and improved operational efficiency.

Constructed with a wear-resistant rubber inner layer and closed-cell foam flotation layer, this hose is suitable for general-purpose dredging applications.

Reinforced with hard steel rings in the inner layer to enhance wear resistance, ideal for transporting highly abrasive materials like gravel and crushed rock.

Lined with embedded ceramic rings or plates on the inner wall, offering superior wear and erosion resistance for highly abrasive media.

Specially designed for bow discharge operations on dredgers, this hose connects to the vessel’s bow and works with a swivel tower or rotary joint.

Suction and discharge hoses are flexible rubber pipelines used in dredging operations to transport slurry, sand, silt, or gravel between dredgers and onshore/offshore locations. These hoses are designed for negative pressure suction or positive pressure discharge applications. With excellent abrasion resistance and structural strength, they are essential components in both floating and submerged dredging systems.

Designed to withstand negative pressure, the suction hose is typically connected to the dredger’s inlet for drawing in dredged materials.

Used on the outlet side of dredging systems to transport slurry under positive pressure, commonly installed on decks or floating pipelines.

Fitted with embedded hard steel rings inside the rubber layer to resist severe abrasion, transporting sharp or heavy materials such as stones and gravel.

Equipped with internal ceramic liners (rings or tiles) for outstanding protection against erosion, particularly in high-abrasion dredging operations.

A combined pipeline system refers to the integrated use of various types of pipes and flotation units to create a customized dredging or slurry transport solution. These systems typically consist of steel pipes, HDPE pipes, pipe floats, and rubber floaters. Designed for both floating and submerged applications, the combined pipeline ensures efficient material flow, stable buoyancy, and adaptability to complex dredging environments.

Pipe floats are HDPE or PE shells filled with PU foam or air, clamped around steel or HDPE pipes to provide buoyancy in floating dredging pipelines.

High-density polyethylene (HDPE) pipes are lightweight, corrosion-resistant, and flexible, commonly used in long-distance or floating dredging pipelines.

Steel pipes offer rigid structure and high-pressure resistance, often used as the mainline in dredging discharge systems, either floating with floats or laid on the seabed.

Rubber floaters are a hybrid of rubber hoses and built-in buoyancy, used to provide floating support and impact resistance for pipeline systems.

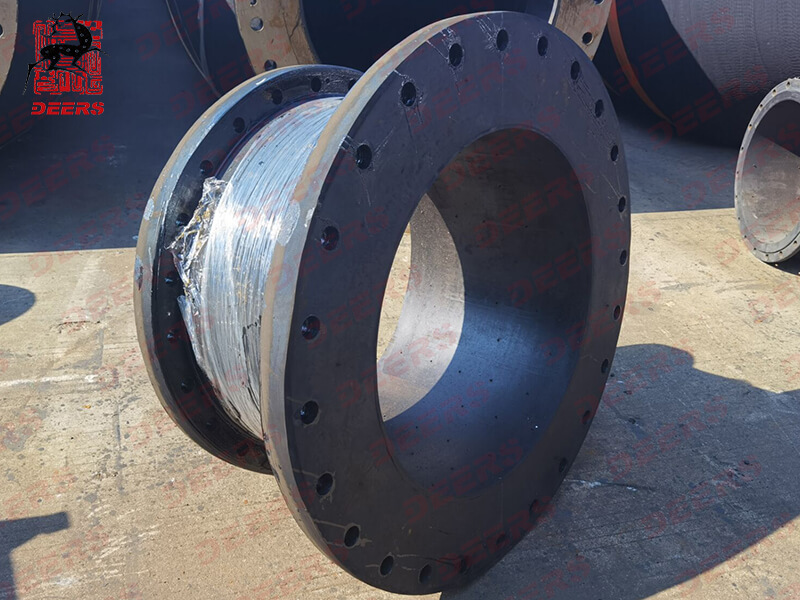

Ball joints are mechanical swivel connectors that allow rotational and angular movement in all directions, commonly used in floating pipeline systems and dredger bow discharge units. They ensure flexibility and secure operation in dynamic marine conditions.

Expansion joints are flexible connectors installed between pipe sections to absorb thermal expansion, contraction, and vibration in dredging and slurry pipelines. They help prevent structural stress, misalignment, and leakage, especially in long or dynamic piping systems.

Ceramic expansion joints are specially designed to absorb thermal movement and vibration while providing exceptional wear resistance in high-abrasion slurry transport systems. The inner lining is made of ceramic rings or tiles, making them ideal for severe dredging or mining applications where conventional rubber joints may fail.

Copyright © 2024 Nanjing Deers Industrial Co.,Ltd All Rights Reserved.