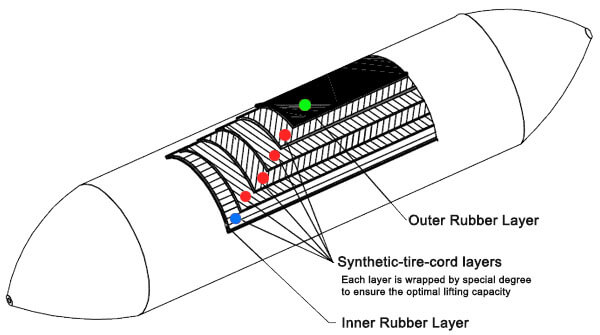

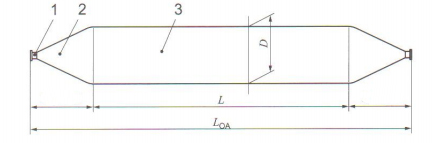

1. Mouth 2. Head 3. Body D: Bag Diameter LOA: Effective Length L: Total Length

Ship launching airbags are constructed of an outer rubber layer, multilayer synthetic-tire-cord layers, and inner rubber layer vulcanized firmly. In addition, the rubber airbags are cylindrical balloon body, with two conical head and end mouth. Swivels and air inlet kits are screwed with end mouth.